Propellers for UAVs

Model Aircraft Propellers

from http://www.airfieldmodels.com/information_source/model_aircraft_engines/propellers.htm

Caution! Some propellers have extremely sharp edges — especially plastic and fiberglass props. For your own safety, scrape and sand this edge down. If you try to flip the propeller by hand, you will get a nasty razor cut as your fingers slide along the back of the blade.

Propellers come in a variety of sizes and styles and are made from five materials that I know of:

- Wood (Maple, Beech or balsa wood on lightweight rubber powered models)

- Nylon

- Fiberglass-reinforced Nylon

- Fiberglass

- Carbon Fiber

Wood, Fiberglass and Carbon Fiber props give the best performance. Nylon props are the least expensive, but they are flexible, cause vibration and rob power.

Do not use nylon propellers!

With the exception of nylon propellers (not to be confused with glass-filled nylon which are fine), all commercially available propellers work well. If you choose a propeller that the engine can swing in its comfort zone then it is a matter of personal preference after that.

Propeller Properties

Pitch is the theoretical distance the propeller will advance along the axis of rotation in one complete revolution.

High Pitch Propeller properties:

- High speed flight

- Poor Acceleration

- Poor Climb

- Can be difficult to slow down for landing

Low Pitch Propeller properties:

- Low speed flight

- Good Acceleration

- Good Climb

- Finer speed control throughout throttle range — particularly at low throttle settings

The easiest way grasp the concept of propeller pitch is to draw a parallel to the gearing in your car.

Low pitch propellers = low gear in your car

It will get you up hills well but will not take you any where fast.

High pitch propellers = Beginning your drive in fifth gear

It will take forever to accelerate to speed but the plane is cruising when it gets there.

Propeller Materials

Wood propellers

Wood propellers are the lightest and present the smallest load to an engine assuming all else is equal (diameter, pitch and shape). They are capable of turning higher RPM than a heavier propeller.

Wooden propellers are also the most easily broken. My opinion is that wood propellers are the most efficient and best performing in the air. Others disagree and they may be right because I'm not a good enough pilot to really have an opinion. In any case, if you nose over your planes often enough then wood propellers are probably a poor choice for you.

Fiberglass-filled nylon propellers

Fiberglass-filled nylon propellers are the heaviest propellers and also the most durable. These are a good choice for beginners because they hold up better than other types to propeller strikes. They are less efficient than wood or carbon fiber propellers, however.

Carbon Fiber propellers

Carbon Fiber Propellers are very rigid, but extremely expensive. I have seen carbon fiber propellers only for large engines. They may be available in smaller sizes in the future.

All of the above propeller materials maintain their shape well under load. Wood and carbon fiber are best.

Fiberglass-filled nylon propellers are the most flexible of propellers that I recommend, but not enough to cause significant problems.

Pure Nylon propellers

Pure Nylon propellers are always a poor choice unless you crash every time you fly. If that's the case, then nylon propellers aren't the answer for you. Stamp collecting is.

Nylon propellers are so flexible that they twist in use which means they are constantly changing pitch. This flexing also creates a lot of vibration. The end result is akin to spinning the wheels of your car — a lot of energy is going to waste. Nylon propellers are just bad. Don't use them.

Weight

Heavier propellers have the advantage of flywheel action . Flywheel action will allow a lower, more reliable idle . Note that all properly designed engines idle reliably anyway, so this is really a moot point.

Another consideration is balancing the aircraft . Personally, I think the best propeller should be chosen for flight qualities, not for weight, but if the aircraft is close to being in balance then changing to a propeller of different weight may put the CG on the money.

Shape

Low RPM engines , such as four-strokes, use wide blade propellers because four-strokes turn fewer RPM. The lower RPM means the air that the trailing blade is entering is less disturbed. Additionally, four-strokes have more torque than two-strokes. Because of this, a four-stroke can swing a wider propeller efficiently.

High RPM engines , such as two-strokes are more efficient with narrow blade propellers due to the more disturbed air caused by the higher RPM.

Number of Blades

Propellers have one, two, three or four blades. Single blade propellers are counter-balanced and used on extremely high rpm racing motors. I've never seen these sold anywhere and suspect they are built by the user. You don't need to even think about these props unless you're building control line speed aircraft. In fact, they may not even be used any more. I haven't been paying attention.

In our realm, the most efficient propellers are two bladed. Because the diameter of our propellers is so small, multiple blade propellers disturb the air that the trailing blade is entering. Therefore, 3 and 4 blade propellers are less efficient.

In general, the only time a 3 or 4 blade propeller should be used is for a more scale appearance or when a smaller propeller disk is necessary.

For example, a scale, twin-engine aircraft may not be able to swing a 2-blade propeller of a small enough diameter to clear the sides of the fuselage. A three and four blade prop can be used here because it can be a smaller diameter and present the same load on the engine.

For best performance with sport aircraft, stick to 2-blade propellers.

Propeller selection chart

from http://www.top-flite.com/accys/topq5000a.html

Propeller aspects

from http://www.bolly.com.au/book/Book.php?Chapter=2&Section=2

One of the biggest problems with propeller design (for all props including ‘full’ size), is that it is impossible to know what a prop is doing in a ‘dynamic’ state. Often static testing does not relate to dynamic performance. It is very easy to develop a prop which gives excellent ‘pull’ on a static test, however a prop designed to these criteria often don’t work that well in the air.

As the average model propeller operates at a Reynolds number (scale effect) similar to a R/C Glider. A high aspect ratio, elliptical based shape generally works best, whether it be for glider wings or a propeller.

The reason multi blade propellers often appear inefficient is the need to use considerable lower diameter propellers (in comparison to 2 blades), for the same horsepower available. Diameter for diameter a well designed 4 blade prop will in some circumstances perform better than the equivalent 2 blade propeller.

Practical strength and aerodynamics means an optimum airfoil thickness of around 15 to 18% near the root, progressively thinning to 10% at the tip. About 12% at the 3/4 span in optimum.

Pitch should always climb from the root to the tip, with the rate of increase being less at the tip - even constant over the last 20% of the diameter. The quoted pitch should always be the 'peak' measurement, although to be more reliable and consistent quoting the pitch at 80% of diameter is the usual practice. The pitch distribution described above is often described as 'progressive pitch', ie - the pitch progressively increases along the blade from root to tip.

The overall design and even the materials from which the propeller is constructed, also have a significant effect on noise. The softer materials such as nylon produce a ‘softer’ noise, but as they are more flexible, the flexing will also create extra noise. To make such a prop rigid will require a thicker blade (heavier and more expensive to produce), which in turn operate at lower rpm (due to absorbing more power), and reduce the propellers overall efficiency. As can be seen, designing for low noise as opposed to high efficiency is a compromise.

The most obvious factor in prop noise is tip speed and shape. Reducing tip speed and using a good tip shape is the most productive method of reducing noise. This will generally mean using a lower diameter higher pitch prop than before.

from http://www.bolly.com.au/1998%20Bolly%20Book%20v3.pdf

Propeller noise is predominantly a product of tip noise. The propeller tip is travelling much faster than any other part of the blade, speed = noise.. A high drag tip shape will always create more noise than a low drag shape, the tip shape will have an effect on the props overall efficiency.

A well rounded or raked tip should always be used, never leave the tip square . The very end of the propeller should be rounded on all sides, not only the leading and trailing corners, as would a model wing tip - never leave it cut off square.

A propeller should NEVER be used over 885 kph without paying attention to tip shape, due to compressibility and shock waves as Mach 1 is approached.

An optimum maximum tip speed for achieving a low noise is 644 kph. There appears to be a marked increase in noise above this speed. The best example of this is R/C Aerobatics where low noise is an advantage. F3A models avoid going above 604 kph tip speed.

Power required to turn a propeller

One can work out the power required to turn a propeller if the propeller moves a volume of air defined by the diameter of the propeller and the theoretical distance the propeller would advance as defined by the pitch in one second. The density of air = Da = is 1.292 kg/cubic metre.

- The volume of air swept out per second = Va = PI * r * r * L

- r = 0.5 * DIA * 0.00254 for DIA in inches (traditionally) and r in metres

- L = PITCH * 0.00254 * RPM / 60 where PITCH is in inches (traditionally) and L is in metres

- Assume very simplistically that the volume of air swept out per second moves at a speed = Sair.

- Kinetic energy = Eke of the volume of air moving at speed = Sair is given by:

- Eke = 0.5 * Mair * Sair * Sair = 0.5 * 1.292 * PI * r * r * L * L

- Eke = 2.4833E-14 * DIA * DIA * (RPM * PITCH) ^ 3 in Watts, DIA and PITCH are in inches

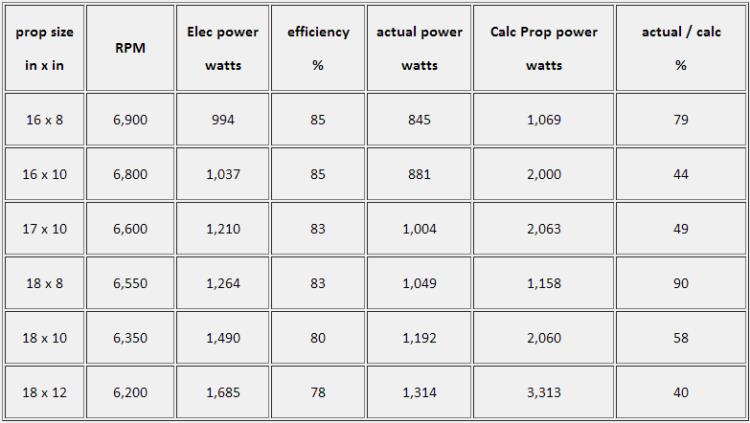

From data on the AXI web site for the new AXI 5320/18 brushless electric motor:

Notes

You need to be very careful with any inferences from the above calculated power. Less engine power was used relative to the calculated value because:

- the air moves at less than the theoretical maximum speed calculated from the pitch of the propeller, so the kinetic energy of the air mass is less.

- The air speed will not be a constant across the diameter of the propeller: it will be less at the centre of the propeller and will increase and then decrease as you move from the centre of the propeller to the edge of the propeller. Consequently, less air is moved at peak speed, so the kinetic energy of the air mass is less.

Some of the actual electrical power input into the motor will go into:

- creating heat in the motor: this is accounted for in engine efficiency

- creating air turbulence

- creating rotational energy in the air mass that does not contribute to thrust

- creating noise, primarily at the tips of the propeller

The typical actual / calculated value is on average 60%. This figure could be used to help us select a suitable propeller for an engine operating at a particular RPM with a rated power output.