Yamaha RMAX Type II G unmanned helicopter

from http://global.yamaha-motor.com/about/business/sky/

During the development stage of the RMAX helicopter, the specs for the various components were determined by taking the following three priorities into consideration:

- The first priority was to pursue the utmost spraying efficiency. The foremost selling point of an unmanned industrial helicopter is its spraying efficiency. Specifically, the payload was doubled, and the spray width was increased to 1.5 times. Furthermore, the helicopter's spray efficiency and ease of use have been dramatically improved by placing cassette-type tanks, a starter motor, and a generator onboard.

- The second priority was to improve reliability. Since it is a flying object, reliability is an extremely important requirement. Thus, the RMAX is equipped with Yamaha's first horizontally opposed engine. For protection from the spray chemicals, all electronic components have been designed with a drip-proof construction. The control electronics consist of a total of 10 CPUs that constantly monitor the components to ensure normal operation. In the event of a failure, the RMAX is equipped with a failsafe function so that it can be controlled without the use of the failed section.

- The third priority was to give the helicopter room for future expansion. In addition to exhibiting the utmost performance in agricultural applications, anticipated new applications have been considered. Examples are mounts to facilitate the attachment of a camera or other devices, the modularization of electronic components, and extra communication ports. Along with the development of new applications, high levels of control, such as autonomous flight control, will be required. Thus, the engineers have kept the performance of a platform that accommodates these requirements in mind.

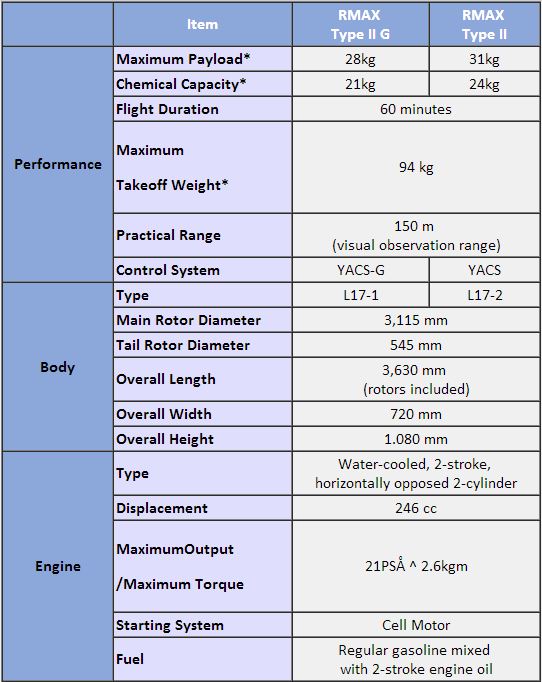

Major Specifications

An exciting world of uses for Yamaha unmanned helicopters

from http://global.yamaha-motor.com/about/business/sky/

Images from the Autonomous Flight RMAX’s CCD camera appear real-time on the PC screen so the operator feels like he is in the pilot’s seat.

In the spring of 2003, Yamaha released the “RMAX Type II G” as the latest development in its RMAX series utility-use unmanned helicopters that first debuted in 1998. The “G” in the new model name stands for the Geographic Positioning System (GPS) technology it mounts and it also boasts major improvements in speed control.

Since its release, the first-year target for RMAX sales of 200 units has already been reached. Presently about 1,600 unmanned helicopters are in use in Japan’s farming industry for crop dusting and other countries are starting to notice the potential of these helicopters.

In this growing field, Yamaha’s helicopters now enjoy an 85% market share. What’s more, beginning this year, Yamaha’s domestic rival Yammar, has begun selling our RMAX Type II G on an OEM basis, giving the RMAX a virtual 100% market share this year.

The RMAX is designed to be carried by two people for ease of use on the farm

Yamaha’s control technologies have also made possible an autonomous flight version of the RMAX that can fly complete flight patterns pre-programmed on a personal computer with no manual remote-control operation necessary. This “Autonomous Flight RMAX” mounts two GPS sensors and other control equipment that enable it to fly constantly within 20 or 30 centimeters of the prescribed flight course. What’s more, when the flight course takes the helicopter out of visual range of the ground operator, the CCD cameras it mounts allow operators to follow the flight progress visually on the PC screen as if they were actually riding in the helicopter.

As was featured in Yamaha News two years ago, this autonomous flight RMAX has already been used for such missions as observation of an erupting volcano in 2000. In 2002, units of this helicopter were supplied to several organizations including the Ministry of Land, Infrastructure and Transport for jobs like river observation and disaster area surveys. And inquiries and orders for these helicopters are starting to pour in from around the world.

Mr. Takafumi Itagaki

In July 2003, the outstanding performance and technologies of the Yamaha RMAX drew much attention when it was demonstrated at an unmanned aircraft exhibition in the U.S. sponsored by the U.S. Navy and the AUVSI and again at other aeronautics shows held after that in nearby cities.

Thanks to attention like this, YMC’s Aeronautic Operations presently receive about 20 inquiries a month from overseas institutions. “We are getting inquiries from government and military officials, major aircraft manufacturers, private-sector research organizations, all types of groups. The world is rapidly coming to recognize the value of Yamaha’s unmanned helicopters” adds Mr. Itagaki.

Agricultural applications of the RMAX helicopter

In the United States, the application of chemicals and seeds from manned airplanes or helicopters gained force early on. This type of application also gained some acceptance in Japan. However, it involved a relatively high cost for the small area of land cultivated per farm household in Japan, and the overspray of the chemicals to the surrounding areas posed problems. Thus, its expansion encountered a standstill.

The reduced number of people working on the farm, and the departure of the younger generation from the farming communities in particular posed a serious problem. Thus, farm work required radical reform. Some ten years have elapsed since Yamaha started the development and sale of practical unmanned industrial helicopters aimed at realizing affluent farming communities.

Today, Yamaha helicopters have fully taken root as the mainstay system for the insect pest control of rice paddies, soybeans, and wheat. Thus, the insect pest control area coverage of Yamaha helicopters has increased by leaps and bounds. This is due in part to the materialization of the low-energy, low-cost production technology under the agricultural policy and the production of environmentally friendly farm products.

But above all, the practicality of the unmanned Yamaha helicopters in terms of super efficiency and effectiveness has been proven, and the customers have understood that the unmanned Yamaha helicopters are indispensable in the future farming style that they visualize.

Based on the trust gained through community-oriented customer support, track record, and reliable technology in production, further expansion of the Yamaha unmanned industrial helicopters is anticipated as a solution for various problems facing the farming communities in Japan and as a contributor to raising the level of food self-sufficiency.